Did you know that 54.6% of business crises occur because companies lose touch with the market and their customers, failing to adapt to changes around them? If businesses stayed stagnant, refusing to adapt or progress, many would quickly fall behind in this fast-changing market.

Growth and innovation thrive on change, and companies that fail to adjust their processes to meet evolving customer demands risk losing their competitive edge. That’s why organizations turn to business process improvement (BPI).

In this blog, we will discuss the essential steps and methodologies of business process improvement, providing a comprehensive guide to help your organization optimize its operations and achieve sustainable growth.

What is a Business Process?

A business process is simply a series of tasks you and your team repeat to deliver a product or service to a customer, stakeholder, or sponsor.

It is like a flowchart that shows each step needed to reach a business goal. A business process starts with a clear objective and ends when that goal is achieved, providing value to the customer. Often, significant processes are broken down into smaller steps so different people or teams can handle different parts of business development.

Types of Business Processes

Operational Processes are the core activities of a business that create value, such as processing customer orders, making products, or opening new accounts. They are essential for achieving operational efficiency.

- Management Processes: These focus on running and overseeing the business, such as budgeting, setting company goals, and managing employees.

- Supporting Processes: These help the core processes run smoothly, like accounting, IT support, or hiring new staff.

Features of a Business Process

- Clear starting and ending points with specific inputs and outputs.

- A set of steps that follow a particular order.

- A focus on who the customer is and how to meet their needs.

- A goal of adding value to the customer or end-user.

- A connection to other processes in the organization.

- It usually involves multiple departments or teams.

It’s helpful to have a process owner in charge of a business process to keep it running smoothly. This person is responsible for ensuring the process works well and finding ways to improve it.

What Is Business Process Improvement (BPI)?

Business Process Improvement (BPI) is better-performing business tasks and activities. It’s a step-by-step method for analyzing, redesigning, and improving your processes to be more efficient and flexible. The goal is to eliminate unnecessary steps, fix bottlenecks, and simplify workflows. This can lead to lower costs, better quality, and happier customers.

To start improving your processes, first, look at how things are currently done. Identify where things slow down, mistakes happen, or resources are wasted. You can do this by checking metrics like how long tasks take, how often errors occur, and how efficiently resources are used.

Once you spot the problem areas, you can redesign the process. This might mean automating repetitive tasks, cutting out steps that aren’t needed, or using new methods and technologies. After making these changes, you’ll need to implement them—this could involve shifting resources, updating team roles, or introducing new systems.

BPI isn’t a one-time fix—it’s about continuously improving how your business works over time. Regularly reviewing and refining your processes can keep your business running smoothly and stay competitive in a changing market.

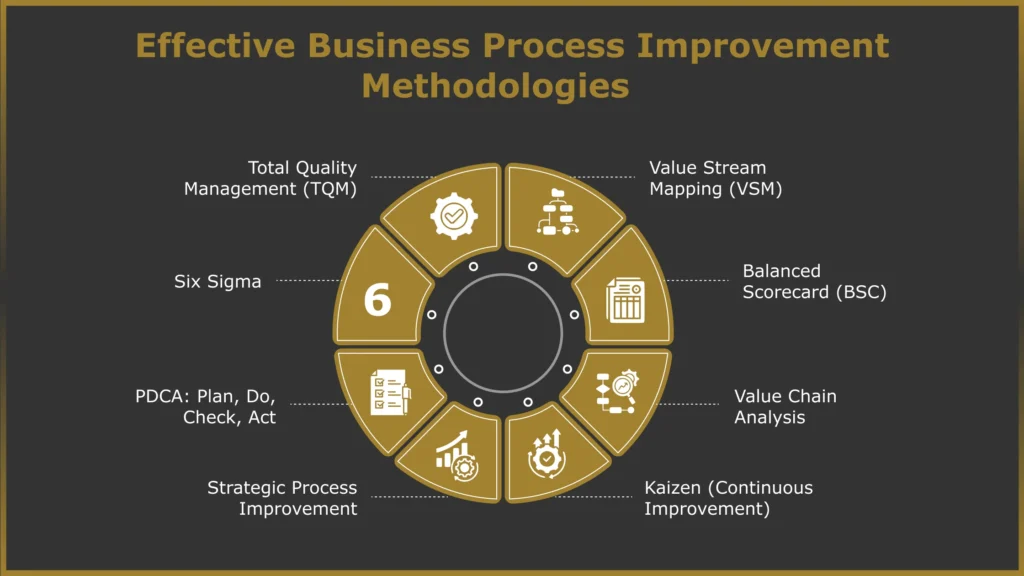

Effective Business Process Improvement Methodologies

Now that we’ve discussed business processes and why they are essential, the next step is understanding how to improve them. This is where process improvement methodologies come into play. These structured approaches help businesses analyze their workflows, identify inefficiencies, and implement changes that improve performance, reduce costs, and increase customer satisfaction.

1. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a visual process for analyzing and optimizing the materials and information required to deliver a product or service.

Initially part of lean manufacturing, VSM helps businesses identify inefficiencies by mapping every step in a process from start to finish. This map highlights value-adding and non-value-adding activities, making spotting bottlenecks, delays, and wasted resources easier. The ultimate goal is to streamline operations, reduce waste, and improve efficiency. VSM promotes better communication across teams and departments, ensuring everyone understands how their roles contribute to the bigger picture.

For example, a manufacturing company might use VSM to discover raw material delivery delays that slow production. Addressing these issues—like finding local suppliers—can help speed up processes, cut costs, and boost productivity.

2. Balanced Scorecard (BSC)

The Balanced Scorecard (BSC) is a strategic management framework that helps organizations align their business activities with their vision and strategy. It goes beyond conventional financial metrics by incorporating non-financial perspectives, offering a more comprehensive view of performance. BSC focuses on four major areas:

- Financial Perspective: Measures profitability, cost management, and revenue growth.

- Customer Perspective: Tracks customer satisfaction, retention, and market share.

- Internal Processes: Evaluate operational efficiency and process improvements.

- Learning and Growth: Focuses on employee development, skills, and organizational culture.

Businesses can identify areas needing improvement while maintaining overall strategic alignment. For example, a company may find that while their financials look strong, customer satisfaction scores are dropping. This insight can prompt a deeper dive into internal processes or employee training, ensuring long-term growth and sustainability.

3. Value Chain Analysis

Value Chain Analysis examines the specific activities within an organization that create value for customers. By dissecting these activities, businesses can identify areas where efficiencies can be improved, costs can be reduced, or differentiation can be enhanced to gain a competitive advantage.

The value chain is divided into two categories:

Primary Activities: These directly contribute to creating and delivering a product or service. They include:

- Inbound Logistics: Receiving and storing raw materials.

- Operations: Transforming inputs into finished products.

- Outbound Logistics: Distributing products to customers.

- Marketing and Sales: Promoting and selling products.

- Service: Post-sale support and customer service.

Support Activities: These provide the necessary background support for primary activities to function efficiently. They include:

- Procurement: Sourcing raw materials and supplies.

- Technology Development: Research, innovation, and process improvements.

- Human Resource Management: Recruiting, training, and employee development.

- Firm Infrastructure: Company systems, policies, and administrative functions.

Businesses can pinpoint bottlenecks, reduce unnecessary costs, and improve areas that drive customer value by analyzing each step in the value chain.

4. Kaizen (Continuous Improvement)

Kaizen, a Japanese term meaning “change for better,” focuses on continuous, incremental improvements in processes, products, and services. Rather than seeking sweeping changes, Kaizen emphasizes minor, consistent enhancements that, over time, significantly improve efficiency, quality, and productivity.

At the heart of Kaizen is the belief that everyone in an organization, from top executives to frontline workers, should be involved in suggesting and implementing improvements. This collaborative approach helps grow a culture of accountability, innovation and shared responsibility for success.

Main principles of Kaizen include:

- Employee Involvement: Encouraging all team members to contribute ideas for improvement.

- Eliminating Waste: Identifying and removing inefficiencies in processes.

- Standardization: Developing consistent procedures to ensure repeatable, high-quality outcomes.

- Feedback Loops: Continuously evaluating and refining processes based on real-time data and employee input.

Organizations that adopt Kaizen often see improvements in operational efficiency, employee morale, and customer satisfaction, creating a sustainable cycle of growth and excellence.

5. Strategic Process Improvement

Strategic Process Improvement (SPI) takes a high-level approach, aligning process enhancements with the organization’s long-term goals and overall strategy. Unlike day-to-day operational tweaks, SPI focuses on transformative changes that drive competitive advantage, efficiency, and sustainable growth.

This methodology evaluates how processes contribute to important business objectives, such as market expansion, cost leadership, or innovation. Organizations can prioritize improvements with the greatest impact by identifying gaps between current processes and strategic goals.

6. PDCA: Plan, Do, Check, Act

The PDCA cycle is a simple yet powerful methodology for continuous improvement. It follows a four-step, iterative process that encourages organizations to test changes on a small scale before fully implementing them. This helps reduce risks and ensures processes are optimized based on real-world results.

Here’s how it works:

- Plan: Identify the problem, set clear objectives, and design a strategy to improve the process.

- Do: Implement the plan on a small scale to test its effectiveness.

- Check: Analyze the results to see if the changes achieved the desired outcomes.

- Act: If the changes are successful, standardize them across the organization. If not, refine the plan and repeat the cycle.

The success of PDCA lies in its cyclical nature—after completing one cycle, the process begins again. This methodology is ideal for businesses making incremental changes while minimizing disruption.

7. Six Sigma

Six Sigma is a data-driven methodology that improves process quality by identifying and eliminating defects or errors. It focuses on achieving near-perfect results by reducing variability in processes.

At its core, Six Sigma uses the DMAIC framework:

- Define: Identify the problem or process that needs improvement.

- Measure: Collect data to understand current performance levels.

- Analyze: Examine the data to pinpoint the root causes of inefficiencies or defects.

- Improve: Develop and implement solutions to address these root causes.

- Control: Monitor the improved process to ensure long-term success and prevent regression.

Six Sigma also assigns roles within the organization, similar to martial arts belts—Green Belts, Black Belts, and Master Black Belts—to denote levels of expertise and responsibility in leading improvement projects. By focusing on data and statistical analysis, Six Sigma helps businesses achieve consistent, high-quality results while reducing waste and costs.

8. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive approach that embeds quality into every organization’s operations. Rather than isolating quality control to specific departments, TQM involves every employee in continuous improvement efforts, from top management to frontline workers. The ultimate goal is to achieve long-term customer satisfaction by consistently meeting or exceeding expectations.

Principles of TQM include:

- Customer Focus: Understanding and prioritizing customer needs at every process stage.

- Continuous Improvement: Encouraging an ongoing cycle of evaluating and enhancing processes, products, and services.

- Employee Involvement: Empowering all employees to take ownership of quality initiatives.

- Process-Centered Approach: Viewing activities as interconnected processes collectively contributing to the organization’s objectives.

- Integrated System: Ensuring all departments and functions align toward common quality goals.

- Data-Driven Decision Making: Using accurate data to guide improvements and monitor performance.

- Communication: Promoting transparent and open communication across all levels of the organization to support quality goals.

TQM often incorporates techniques from other methodologies like Kaizen and Six Sigma, making it a versatile framework adaptable to various industries. Organizations that embrace TQM can expect improved efficiency, reduced costs, and a stronger competitive edge through enhanced product and service quality.

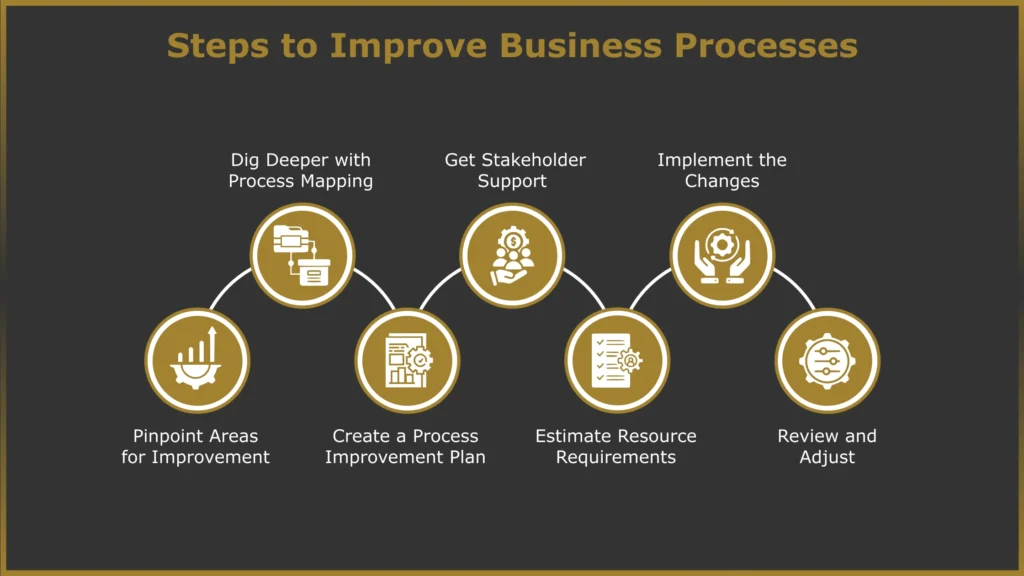

Steps to Improve Business Processes

Improving your business processes can lead to fewer mistakes, faster results, and happier customers. But how do you get started? Here’s a straightforward guide to help you cut down on waste, boost efficiency, and streamline your operations.

1. Pinpoint Areas for Improvement

Start by taking a step back and looking at your business processes from a big-picture perspective. What’s not working? Where are the delays or recurring errors? Conduct a process audit to uncover weak spots and inefficiencies. This will give you a clear idea of where to focus your efforts.

2. Dig Deeper with Process Mapping

Once you know what needs fixing, it’s time to get into the details. Use flowcharts or swim lane diagrams to map out each process step. This visual representation will help you spot bottlenecks and unnecessary steps. Ask questions like:

- Where are things slowing down?

- What steps are eating up too much time or resources?

- Are we spending more money than necessary?

- Is the quality of our output suffering?

Talk to team members involved in the process. They will have valuable insights into what’s going wrong and ideas for improvement.

3. Create a Process Improvement Plan

Now that you’ve identified the problem areas, it’s time to develop a plan. Outline the specific changes you want to make, keeping in mind the feedback from your team. Start by brainstorming ideas without worrying about limitations like cost or time. After gathering ideas, narrow them down by evaluating the risks, feasibility, and potential impact. Once you settle on a realistic plan, document the new process with updated diagrams to guide implementation.

4. Get Stakeholder Support

Before moving forward, you’ll need approval from major stakeholders, especially senior management. Since process changes can take time and require resources, having their backing is essential. Present a clear case for why these changes will benefit the business, using data and examples from your analysis to strengthen your argument.

5. Estimate Resource Requirements

With your plan in place, list all the resources you’ll need to implement the changes, including budget, technology, or additional staff. Go through the proper channels to secure approval for these resources and explain how they will improve the process. A solid business case can help justify the investment.

6. Implement the Changes

Now, it’s time to implement your plan. Treat this like a project: assign roles, allocate resources, set timelines, and manage risks. You might also need to update systems, restructure teams, or adjust workflows. Keep communication open with everyone involved to ensure a smooth transition.

7. Review and Adjust

Once the changes are in place, don’t just walk away. Monitor the results closely to see if they deliver the expected improvements. Are processes running more smoothly? Are costs down and customer satisfaction up? Regularly check in with your team to get feedback on the new process. Be prepared to make adjustments to fine-tune the process and ensure continuous improvement.

Achieve Seamless Process Improvement with Expert Guidance

If you’re ready to streamline your business processes and boost efficiency, Outcomes COO can help you achieve lasting results. Our Fractional COO services let you focus on growth while we handle the operational complexities.

Here’s how we can support your business:

- Reclaim Your Time: Delegate day-to-day operations to experienced leaders, freeing you to focus on strategy and innovation.

- Streamline Operations: Implement proven EOS® principles to optimize workflows and reduce inefficiencies.

- Foster Accountability: Build a culture of ownership and responsibility within your team for sustained growth.

- Drive Business Growth: With operations running smoothly, you can pursue new opportunities and expand confidently.

- Flexible Fractional Leadership: Get expert guidance without the full-time commitment tailored to your unique business needs.

Transform your operations into a well-oiled machine while you focus on what matters most—growing your business!